Table of Contents

- What Regulations Are Applicable to Dust Collectors?

- How Does the Project Scope Affect the Ideal Type of Dust Collector?

- What Are the Key Components of an Industrial Pulse Jet Dust Collector?

- Baghouse vs. Bin Vent vs. Cartridge Dust Collectors

- The Industrial Dust Collector Design Process

- How Much Does a Dust Collection System Cost?

- Dust Collector Maintenance Considerations

- Industrial Dust Collector Systems From U.S. Air Filtration

Dust collection systems are key to maintaining appropriate conditions for employees and equipment in industrial workspaces. Dust collectors are designed and constructed to filter airborne dust and debris that can cause injury or illness to employees, damage or degrade equipment, and negatively impact plant production. In light of this important function, it is essential to choose the right dust collection system to maintain a clean, productive, and compliant work environment. Below is an overview of some of the considerations to keep in mind when designing and selecting a dust collector system.

What Regulations Are Applicable to Dust Collectors?

Certain industrial operations—e.g., chemical manufacturing, food processing, and metalworking/woodworking—generate significant amounts of airborne dust and debris. As these compounds can negatively affect human health, numerous federal, state, and local regulatory organizations—e.g., the Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and National Fire Protection Association (NFPA)—impose strict guidelines aimed toward preventing employees and passersby from exposure. One key method industry professionals employ to comply with regulations is integrating dust collector equipment in their facility to minimize dust accumulation.

In addition to choosing the right dust collector for a facility, plants are required to attain the right permits. Air permits are legal documents provided by a local or state agency to businesses that generate above a certain level of air pollution. Air quality permits indicate the air emission guidelines—e.g., air pollution limitations, control equipment requirements, and filtration efficiencies—to which the business must comply. These guidelines may vary by municipality, country, or state. Factors that impact air permitting requirements include plant size, application, industry, and equipment employed. As such, it is essential to communicate with the governing body closest to the facility’s location to acquire the most relevant information.

How Does the Project Scope Affect the Ideal Type of Dust Collector?

The dust collection expectations of a facility significantly influence the type of dust collector that should be employed. Some of the factors to keep in mind when choosing a dust collector design include:

Type of material. The following dust properties influence which dust collection method is most effective:

- Size (small or large)

- Bulk density (loose or compact)

- Composition (acidic or basic)

- Temperature (room temperature or elevated)

- Moisture level (low or high)

For example, baghouse dust collectors are suitable for sticky and high-temperature dust, while cartridge dust collectors are more appropriate for finer dust particles. If the dust is highly explosive or flammable, a spark detection system, explosion vent, or sprinkler vent may be necessary.

- Daily dust disposal quantities. Estimated dust disposal volume and frequency helps determine which discharge method is most convenient. For example, bin vent and cartridge collectors are suitable for lower volumes of dust, while baghouse dust collectors are better suited for large volumes of dust greater than 55 gallons per day.

- Air velocity (in FPM). The velocity requirements in a dust collector depend on the weight of dust particulate; the heavier the dust, the greater the speed required to convey dust particulate through the dust collection system.

- Air-to-cloth ratio. also referred to as the air-to-media ratio—is the amount of air that passes through one square foot of filter media. While a lower air-to-cloth ratio is generally indicative of better filtration efficiency, optimal ratio depends on the particular dust collection system and the facility.

What Are the Key Components of an Industrial Pulse Jet Dust Collector?

Dust collector systems are generally tailored to accommodate specific workspace and air purification needs. Although the exact components vary from system to system, all dust collectors consist of the following elements:

- A blower to facilitate the movement of air through the system

- A ductwork system to contain the dust-laden air as it moves through the system

- A filter to capture dust

- A filter cleaning system and discharge mechanism for dust removal

- A dust receptacle to temporarily store the dust

- A dust removal system to dispose of the collected dust

- A control panel to automate each cleaning cycle

https://www.youtube.com/watch?v=15wtH87_p6I&t=121s

Baghouse vs. Bin Vent vs. Cartridge Dust Collectors

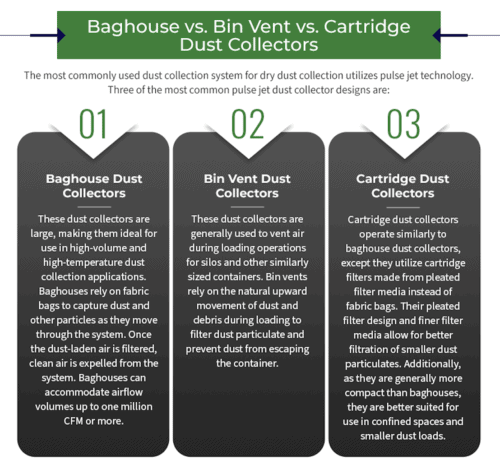

As indicated above, dust collectors share many of the same basic components. However, the design and construction of these elements may vary depending on the type of dust collector. The most commonly used dust collection system for dry dust collection utilizes pulse jet technology. Three of the most common pulse jet dust collector designs are:

- Baghouse dust collectors: These dust collectors are large, making them ideal for use in high-volume and high-temperature dust collection applications. Baghouses rely on fabric bags to capture dust and other particles as they move through the system. Once the dust-laden air is filtered, clean air is expelled from the system. Baghouses can accommodate airflow volumes up to one million CFM or more.

- Bin vent dust collectors: These dust collectors are generally used to vent air during loading operations for silos and other similarly sized containers. Bin vents rely on the natural upward movement of dust and debris during loading to filter dust particulate and prevent dust from escaping the container.

- Cartridge dust collectors: Cartridge dust collectors operate similarly to baghouse dust collectors, except they utilize cartridge filters made from pleated filter media instead of fabric bags. Their pleated filter design and finer filter media allow for better filtration of smaller dust particulates. Additionally, as they are generally more compact than baghouses, they are better suited for use in confined spaces and smaller dust loads.

The Industrial Dust Collector Design Process

When planning the design and construction of a dust collection system, it is important to have a clear understanding of how the system should perform within the facility. As indicated above, some of the factors to keep in mind include dust type, dust collection volume, air velocity, and air-to-cloth ratio. These considerations, among others, influence how the system should be designed and constructed.

Three of the design elements affected by these factors are:

- Dust collector ductwork serves as a transportation network for the dust-laden air within the dust collector. Ductwork size and complexity depend on the size and complexity of the system, while diameter depends on the type of dust generated and its expected volume and velocity. During the design and construction of this system element, limiting the complexity (i.e., using straight lines and minimal curved or transitional elements) and size helps ensure better system efficiency.

- Dust removal mechanism. The ideal dust removal mechanism depends on the type of dust collector employed, the type of dust being collected, and the dust loading rate. The main mechanisms utilized include:

- Enclosed box (i.e., a pipe system funnels dust into an enclosed box),

- Drum or bag (i.e., the drum or bag is removed, emptied, and replaced once it is full),

- Rotary valve (i.e., the valve allows dust to flow from the dust collector into a drum or bin)

- Screw conveyor (i.e., a screw conveyor carries collected dust from the system to a designated storage/disposal area).

- Explosion venting. If the dust collected by a dust collection system is combustible, appropriate measures—such as integrating explosion vents or panels, flameless venting, or spark detection and extinguishing systems—should be implemented to minimize the risk of explosion and fire outbreaks.

How Much Does a Dust Collection System Cost?

Dust collectors vary in size, ranging from the compact units used in small, residential or hobby workshops to the large-scale systems designed for industrial facilities. Smaller units—accommodating airflows up to 1,000 cubic feet per minute (CFM)—generally cost between $100 to $5,000, and are suited for small, residential shops, while larger units—handling airflows between 2,000 to 10,000 CFM—cost between $10,000 to $80,000, depending on the unit size, filter media, and fan size. Custom dust collection systems for highly specific or unique applications range between $50,000 to $1 million, depending on the system requirements.

Some of the main factors that influence the cost of a dust collection system are:

- Dust type: what is/are the dust’s composition, properties, particle size, combustibility, temperature, moisture level, etc.?

- Dust load: how much dust must be removed from the air?

- Filter media: what filter media is used in the system?

- Air-to-cloth ratio: how much air should pass through the filter media?

- Fan size: what fan size is integrated into the system?

- Material handling and conveying: what material handling/conveying elements are integrated into the system to ensure efficient and effective dust removal?

- Paints, coatings, or unit insulation: does the system require specialized paints, coatings, or insulation to ensure its durability?

- Electric controls or accessories: what electrical controls and accessories are necessary for proper system function?

Dust Collector Maintenance Considerations

Once a dust collector system is designed, constructed, and installed in a facility, it is essential to implement an adequate maintenance program to ensure it continues to provide effective and efficient performance throughout its service life. Below we outline some of the typical steps in a maintenance program.

- Verify the system operates within acceptable ranges (e.g., air pressure to solenoid valves, timing controls for pulse valves, compartment differential pressure, etc.)

- Check the condition of the filter media, fan bearings, damper valves, door seals and gaskets, and other system components and repair/replace them if necessary

- Empty the dust in the hopper if necessary

https://www.youtube.com/watch?v=dqlG8sqi9A4&t=62s

It is important to employ the proper safety measures to protect against injury during any maintenance operation. For example, when performing maintenance inside of a baghouse dust collector:

- Ensure the unit is powered and locked down

- Employ the proper personal protective equipment (PPE)

- Designate a lookout

- Communicate the specifications of the operation (what, where, when, etc.) to all other employees

- Verify combustible dust inside of the system is within safe levels

- Formulate an emergency escape/retrieval plan

For additional maintenance tips, check out U.S. Air Filtration’s Dust Collector Maintenance Checklist.

Industrial Dust Collector Systems From U.S. Air Filtration

For over 40 years, U.S. Air Filtration, Inc. has designed and manufactured standard and custom dust collection systems for customers around the world. We provide baghouse dust collectors, bin vent dust collectors, and cartridge dust collectors. To learn more about our design and manufacturing capabilities, check out our design services page or dust collector purchasing guide. For further assistance designing or selecting a dust collector for your facility, contact us or request a quote today to schedule an engineering consultation.

For maintenance, troubleshooting and other resources, watch our video "How Much Does a Dust Collector Cost?", subscribe to our YouTube channel, follow us on Twitter, and like us on Facebook & LinkedIn.