A critical part of the dust collection design process is where to position your baghouse inlet. The purpose of the baghouse inlet is to draw dirty, dust laden air into the system so the air can be filtered. In this article, we will focus on the design factors that help determine a system’s inlet placement (high versus low), can velocity, and the advantages of a high inlet versus a low inlet baghouse.

When designing a dust collection system, we consider your dust properties and the characteristics of your work environment carefully to identify the best solution. Below are the five most critical dust collection design elements.

During the design process, we consider two primary characteristics that influence baghouse inlet placement:

When you have a large amount of dust and that dust is heavy, a dust collection system may benefit more from a low inlet design. When heavy dust enters the unit at the bottom of the system, the natural force of gravity will pull the dust down. Conversely when you have light to medium dust loading and very light dust, a dust collection with a high inlet design would typically be best.

However, even in similar environments the dust loads, work environment, and space can vary drastically. Our best recommendation is to work closely with your U.S. Air Filtration equipment specialist. Understanding all the details and nuances to your specific project will allow us to make the best design recommendations.

Can velocity is the speed at which air moves from low in the baghouse to high. The higher the can velocity, the faster air moves up in the system. We calculate can velocity based on your CFM, the size of the collector, and your space restrictions.

During the design process, your equipment specialist can help determine if there will be a high enough can velocity that would require a high inlet. A high inlet will eliminate or counter can velocity. This way, dust can drop or if the dust is heavy enough, the dust will overcome upward air movement and drop out without issue.

CFM, space restrictions, and dust loads are all straightforward questions. But depending on the answers provided there can be different results. Here are two different scenarios that could occur during the design process that require two different inlets.

When considering a high versus low inlet for your dust collection system, there are certain design advantages that are considered based on dust type and application. There are additional costs for a high inlet baghouse. If your project will allow for a low inlet design, then that’s the route we recommend. Our goal is to help you avoid spending more money than necessary both upfront and in long term maintenance costs.

However, in certain situations it may be worth investing in a high inlet. These situations include:

In these cases, it may be worth spending the extra money to design a dust collection system with a high inlet, to avoid these issues. You will also have the added benefit of avoiding additional maintenance problems down the road.

What if your application has light dust, but high dust loading? An additional option in this case would be an end inlet. This helps bring in the dust in high, but as it hits a baffle, it redirects the air directly downward. In this scenario, heavy part particulate hits the baffle, then slow down, and drop out. Then it kicks the rest of the air down below the bag, so you still have can velocity. However, we reduce the amount of dust in the airstream so much that can velocity is not as much of a concern as if it was just a standard low inlet baghouse. The disadvantage to an end inlet is those baghouses tend to be considerably larger because you must have space for that air to hit the baffle.

At U.S. Air Filtration, our V.P. of Engineering, generally recommends a low hopper entry or side entry inlet baghouse with a full blast height plate/drop-out box plenum, if the particulate from the process is highly abrasive and/or has a bulk density of greater than 70 lbs./CF. (I.e., Sand, silica, glass, etc.) If you have questions regarding this exception, please contact U.S. Air Filtration’s engineering department for further explanation.

At U.S. Air Filtration, we understand that a dust collection project may just be one piece of a larger project for you. Our engineers are here to help solve your concerns and design a solution that best fits your application and facility. If you need to speak with an equipment specialist, please feel free to contact us at 888-221-0312 or email info@usairfiltration.com. If you’re just starting your dust collection project, access our “Dust Collector Purchasing” article for more information on design considerations, airflow, air-to-cloth ratio, and more.

Dust Collection System Design Factors

When designing a dust collection system, we consider your dust properties and the characteristics of your work environment carefully to identify the best solution. Below are the five most critical dust collection design elements.

Dust Collection Design Factors

- Dust Properties

- Your Work Environment

- Space Constraints

- Emissions Requirements

- Temperature of the Environment

During the design process, we consider two primary characteristics that influence baghouse inlet placement:

- The amount of dust you are bringing into the collector

- The heaviness of the dust

When you have a large amount of dust and that dust is heavy, a dust collection system may benefit more from a low inlet design. When heavy dust enters the unit at the bottom of the system, the natural force of gravity will pull the dust down. Conversely when you have light to medium dust loading and very light dust, a dust collection with a high inlet design would typically be best.

However, even in similar environments the dust loads, work environment, and space can vary drastically. Our best recommendation is to work closely with your U.S. Air Filtration equipment specialist. Understanding all the details and nuances to your specific project will allow us to make the best design recommendations.

Can Velocity and Dust Collection Design

Can velocity is the speed at which air moves from low in the baghouse to high. The higher the can velocity, the faster air moves up in the system. We calculate can velocity based on your CFM, the size of the collector, and your space restrictions.

During the design process, your equipment specialist can help determine if there will be a high enough can velocity that would require a high inlet. A high inlet will eliminate or counter can velocity. This way, dust can drop or if the dust is heavy enough, the dust will overcome upward air movement and drop out without issue.

CFM, space restrictions, and dust loads are all straightforward questions. But depending on the answers provided there can be different results. Here are two different scenarios that could occur during the design process that require two different inlets.

Baghouse Inlet Scenario 1:

- No design preference for the inlet.

- No space issues

- In this case, it’s possible for a customer to have a system that’s designed to hold 700 filter bags, 8’ in length, with a low inlet. This scenario is possible with just about any type of dust. All that is needed to drive that air to cloth ratio down as low as possible, is to eliminate as much can velocity as you can. As a result, your dust collection system will work as intended with a low inlet design

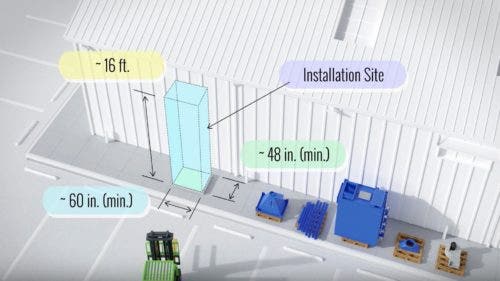

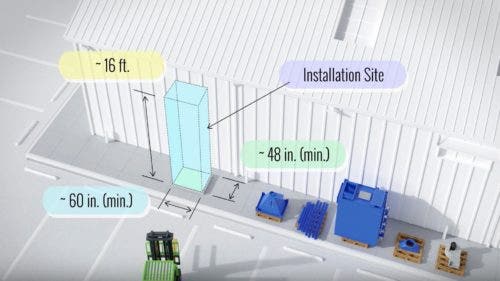

Baghouse Inlet Scenario 2:

- No design preference for the inlet.

- Yes, there are space constraints.

- In this example, if there is only a 15’ by 15’ space to install a dust collection system, the system must be taller and require longer filter bags of 12’ to adequately handle the dust load. filter bag. By design, there will be a much higher can velocity even though the same air to cloth ratio is being used. This is because the filter bag is longer, the dust collector is thinner, more vertical rather than wider, and shorter. These factors all increase can velocity. Because the can velocity is higher, a high inlet would be required to allow better dust dropout.

High versus Low Inlet Dust Collector Design Advantages

When considering a high versus low inlet for your dust collection system, there are certain design advantages that are considered based on dust type and application. There are additional costs for a high inlet baghouse. If your project will allow for a low inlet design, then that’s the route we recommend. Our goal is to help you avoid spending more money than necessary both upfront and in long term maintenance costs.

However, in certain situations it may be worth investing in a high inlet. These situations include:

- When you are worried about the dust not dropping out of the airstream

- If you’re concerned the bags won't clean properly

- If you are afraid you are going to lose suction over time

In these cases, it may be worth spending the extra money to design a dust collection system with a high inlet, to avoid these issues. You will also have the added benefit of avoiding additional maintenance problems down the road.

Additional Baghouse Inlet Options

What if your application has light dust, but high dust loading? An additional option in this case would be an end inlet. This helps bring in the dust in high, but as it hits a baffle, it redirects the air directly downward. In this scenario, heavy part particulate hits the baffle, then slow down, and drop out. Then it kicks the rest of the air down below the bag, so you still have can velocity. However, we reduce the amount of dust in the airstream so much that can velocity is not as much of a concern as if it was just a standard low inlet baghouse. The disadvantage to an end inlet is those baghouses tend to be considerably larger because you must have space for that air to hit the baffle.

The Design Process with U.S. Air Filtration

At U.S. Air Filtration, our V.P. of Engineering, generally recommends a low hopper entry or side entry inlet baghouse with a full blast height plate/drop-out box plenum, if the particulate from the process is highly abrasive and/or has a bulk density of greater than 70 lbs./CF. (I.e., Sand, silica, glass, etc.) If you have questions regarding this exception, please contact U.S. Air Filtration’s engineering department for further explanation.

At U.S. Air Filtration, we understand that a dust collection project may just be one piece of a larger project for you. Our engineers are here to help solve your concerns and design a solution that best fits your application and facility. If you need to speak with an equipment specialist, please feel free to contact us at 888-221-0312 or email info@usairfiltration.com. If you’re just starting your dust collection project, access our “Dust Collector Purchasing” article for more information on design considerations, airflow, air-to-cloth ratio, and more.